30.08.2017

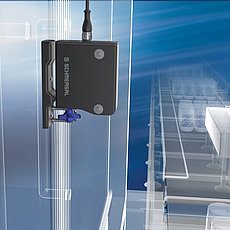

First Complete Compliance with ISO-14119: New AUX Power Version of AZM 300-AS

Schmersal presents efficient safety solutions for complex machinery at the Motek

The new AUX variant of the AZM 300 AS, a solenoid interlock with integrated AS-i-Safety-at-Work interface, achieves the highest safety level PL e with the safe two-channel release function. Therefore, it is worldwide the first AS-I solenoid interlock which meets all user requirements of the ISO 14119 standard. Thanks to the integrated RFID technology AZM300-AS achieves the coding level ‘high’ thus ensuring a high protection against manipulation according to ISO 14119. Apart from the AUX power version the AZM300 solenoid interlock is also available in the AS-i power variant. The fieldbus standard AS-i is used to connect non-safe as well as safe switches, sensors and interlocks in a simple and cost-effective way. AS-i safety solutions therefore offer a variety of diagnosis options and enable an early fault detection for instance. This is an important feature in terms of preventive maintenance and industry 4.0. AS-I-Safety-at-Work also allows for individually scalable safety solutions for different machine sizes with simple and fast assembly.

The Schmersal Group expands its AS-i program continuously, offering a very comprehensive range of safety components with AS-i interface. Schmersal Safety installation systems

The new Schmersal Safety Installation Systems support users in their use of series connection of different safety switching devices such as safety sensors and solenoid interlocks within larger safety functions and enable simple, failsafe and cost-optimized wiring solutions. With the new installation systems PDM and PFB, larger systems can be constructed thanks to the cascading

capability. Wire cross sections of up to 1.5 mm² reduce voltage drops in the supply cables. The internal autoreset fuses for each safety interlock saves the mandated individual fuse when the wire cross section is reduced.

Passive installation systems can be equipped with a serial diagnosis (SD) interface to transmit non-safe data. Safety sensors and solenoid interlocks in a series connection equipped with SD interface can transmit comprehensive diagnosis data via SD gateway and a fieldbus to a control system, and data is visualized. The evaluation of non-safe diagnosis data by the control system allows for a preventive maintenance. Maintenance costs are therefore kept to a minimum by adapting maintenance cycle to the requirements. Visit Schmersal at Motek in Stuttgart, Germany, from 9 to 12/10/2017: Hall 7, Stand 7103